Fire safety of wooden houses – facts and standards

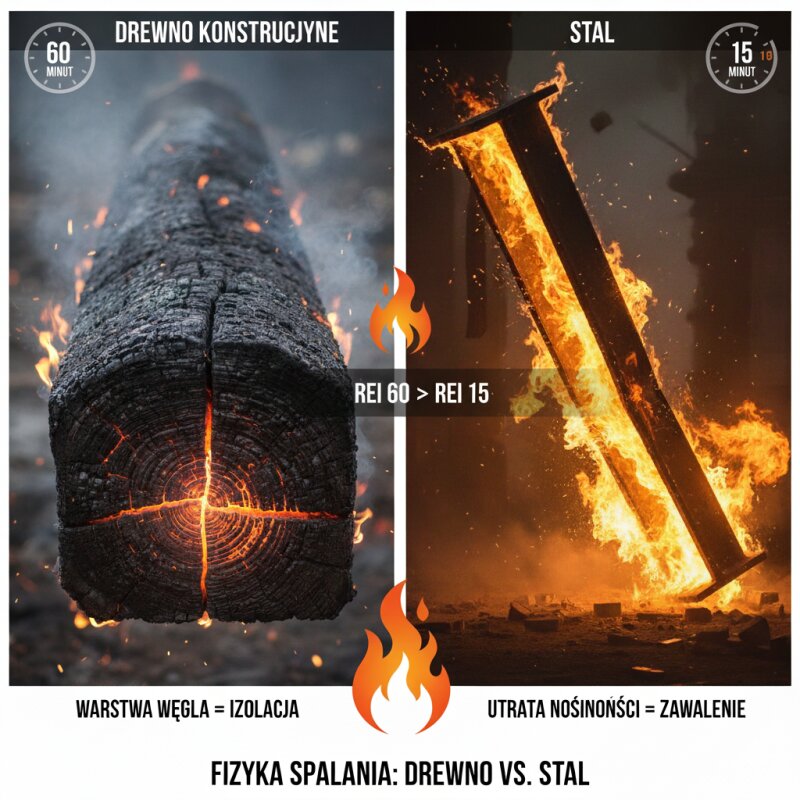

Combustion physics: Structural Timber vs. Steel

Let's start with a fact that surprises investors the most. In the event of a developed fire, a massive wooden structure often behaves more predictably and safely than an unprotected steel structure. Why?

Steel under the influence of high temperature instantly loses its load-bearing properties. It softens, bends, and the structure can collapse violently, without warning. It should be emphasized that unprotected steel, especially in structures where the element is under heavy load, actually loses its load-bearing properties very quickly in high fire temperatures (above about 500-600°C). This can happen within a few to a dozen minutes. Steel changes its crystal structure, becomes plastic, and loses rigidity, which leads to deflections and sudden collapse. Without appropriate protection (such as intumescent paints or fireproof boards), steel is a material with very low fire resistance regarding load-bearing capacity.

With wood, this process looks different. When fire consumes a thick wooden beam, a charred layer forms on its surface. This charcoal acts as a natural insulator. It cuts off the oxygen supply to the deeper layers of the beam and slows down the temperature rise inside the load-bearing element.

Thanks to this phenomenon, structural timber "defends" itself, maintaining load-bearing capacity for a certain time (e.g., 30 or 60 minutes), which gives the fire brigade time for action and the residents time to evacuate. The structure does not "flow" like heated steel. Indeed, massive structural timber can retain its load-bearing capacity for a surprisingly long time in a fire, precisely thanks to the formation of a charred insulating layer. REI standards (Load-bearing capacity, Integrity, Insulation) for wood can be REI 30, REI 60, and even more (e.g., for very thick beams). Much depends on the thickness of the wooden elements, the type of wood, and also on whether it is covered with additional materials, such as plasterboards or mineral wool. In the context of the text, 60 minutes is a realistic goal to achieve for well-designed wooden structures.

Impregnation and processing: Why does fire "slide" on wood?

Have you ever tried to light a fire in a fireplace with a thick, smooth log without using kindling? It is almost impossible. It is similar with C24 structural timber used in System-S.

The secret lies in mechanical processing. The wood is planed on four sides and has chamfered edges. What does this give in the context of fire safety?

- Smooth surface: Flames have no foothold. Fire "slides" along the smooth beam instead of penetrating its structure, as is the case with hairy (unplaned) wood.

- No splinters: It is the small elements that catch fire first. C24 wood is free of them.

And what about impregnation? It is worth emphasizing that structural timber, although it is a combustible material, is often subjected to additional impregnation with fire retardants. These impregnations do not make the wood non-combustible, but significantly limit its ability to ignite and slow down the spread of fire. They work in various ways: they can form a non-combustible insulating layer on the surface, release flame-suppressing gases, or increase the wood's ignition temperature. In combination with a smooth, planed surface and lack of splinters, appropriate impregnation additionally increases the safety of the structure, making it difficult to ignite and develop a fire from the initial phase.

Protective armor: Plasterboards and Rock Wool

You must know one key thing: in a properly built frame house, fire rarely has a chance to touch the wooden structure at all. The wood is "enclosed" in a system of non-combustible materials.

- Fire resistance of plasterboards: Internal walls and ceilings are lined with plasterboards (often with increased fire resistance, marked in pink). Gypsum contains water in its crystal structure (about 20%). During a fire, this water evaporates, which effectively cools the wall and stops the fire from reaching the frame for several dozen minutes.

- Mineral/rock wool: The wall filling is wool, which has a reaction to fire class A1 (non-combustible material). Rock wool withstands temperatures exceeding 1000°C. It acts as a fire shield, not allowing flames to spread inside the partitions.

REI Standards – safety mathematics

In construction, there is no place for "I think so". Every building, regardless of technology, must meet strict fire protection standards. For single-family houses, the key parameter is REI fire resistance.

- R (Load-bearing capacity): How long the structure will support the weight during a fire.

- E (Integrity): How long the wall will not let flames and gases through to the other side.

- I (Insulation): How long the wall will not heat up on the other side to a temperature that could start a fire in the adjacent room.

System-S frame houses are designed to meet the legally required standards (usually REI 30 or REI 60). This means that in fire conditions, the wall will withstand a minimum of 30 or 60 minutes of full fire pressure. This is a standard identical to masonry buildings.

Is a frame house flammable? Summary

The answer is: the structural material itself (wood) is combustible, but the finished house – as a system of partitions – is highly resistant to fire. The combination of planed wood, non-combustible wool, gypsum boards, and potential impregnation creates a safe living space. The risk of fire in a house does not result from wall construction technology, but usually from faulty electrical installation or human error (e.g., in the kitchen). And we protect ourselves against these factors in the same way in a wooden house as in a concrete one – by using good quality equipment and maintaining common sense.